Old building trick translates on nano-scale

The technique improves both the structural integrity and the electrical conductivity of graphene, and could help bring about full-scale commercial graphene production.

The use of reinforcing bars, or ‘rebar’, has been strengthening buildings and concrete constructions for some time, and now appears to help make large, flexible, conductive and transparent sheets of graphene much easier to manipulate.

Carbon nanotubes are used as reinforcement for graphene sheets, which researchers from Rice University in the US say could make it easier to produce.

Graphene is a single-layer matrix of carbon atoms, and may be one of the strongest materials on the planet. However, it has been a challenge to lift the tiny sheets from the catalyst substrate on which they’re grown, generally by chemical vapour deposition (CVD).

“Normally you grow graphene on a metal, but you can’t just dissolve away the metal,” chemical engineer Dr James Tour said.

“You put a polymer on top of the graphene to reinforce it, and then dissolve the metal.

“Then you have polymer stuck to the graphene. When you dissolve the polymer, you’re left with residues, trace impurities that limit graphene’s effectiveness for high-speed electronics and biological devices. By taking away the polymer support step, we greatly expand the potential for this material.”

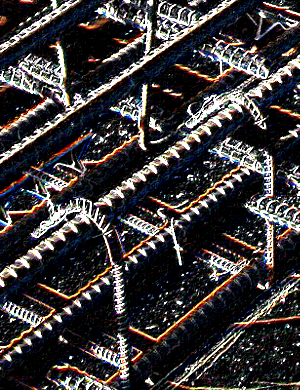

To create their “rebar graphene”, the researchers spin-coated, heated and cooled functionalised single- or multi-walled carbon nanotubes on copper foils, using the ‘tubes themselves as the carbon source.

When heated, the functional carbon groups decompose and form graphene, while the nanotubes partially split and form covalent junctions with the new graphene layer.

“The nanotubes actually become one with the material in certain places,” Dr Tour said.

It’s a true hybrid with in-plane nanotubes covalently bonded to graphene.”

The interconnected, embedded nanotubes strengthen the graphene.

“We can see in our images how well the nanotubes bear the load. When we stretch the material, the tubes get thinner,” Dr Tour said.

The network of nanotubes also makes the material a better conductor than standard CVD-grown graphene.

Graphene as typically grown is an imperfect matrix of hexagons; it consists of crystals that grow separately and connect at grain boundaries that disrupt the flow of electrons.

The nanotubes in rebar graphene effectively bridge those boundaries.

The material will be used for a broad range of applications in the future, including devices of incredible strength and durability, as well as vast improvements in electrical storage and conductance abilities.

The research appears in the latest American Chemical Society journal ACS Nano.

Print

Print